PRODUCTS » MIST ELIMINATORS

PRODUCTS » MIST ELIMINATORS

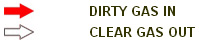

The EVERON range of mist eliminators are the Chevron type of mist eliminators which consist of a set of specially designed vanes with a well defined geometry. Gas with entrained liquid droplets flows between the vanes of the EVERON Separator. The gas can easily take the turns while the liquid droplets cannot follow the gas streamlines and impinge upon the walls of the vanes and coalesce to a size where they drop down and are collected and removed.

The EVERON VHF (Vertical Flow - Horizontally Palced)

This mist eliminator is designed for vertical gas flow. In this onfiguration the vanes are designed to provide optimum deflection to the gas containing entrained liquid particles.

The entrained particles cannot follow the deflected gas path and are collected as they accumulate along the wall of the mist eliminator. Collected liquid runs down counter current to the direction of gas flow.

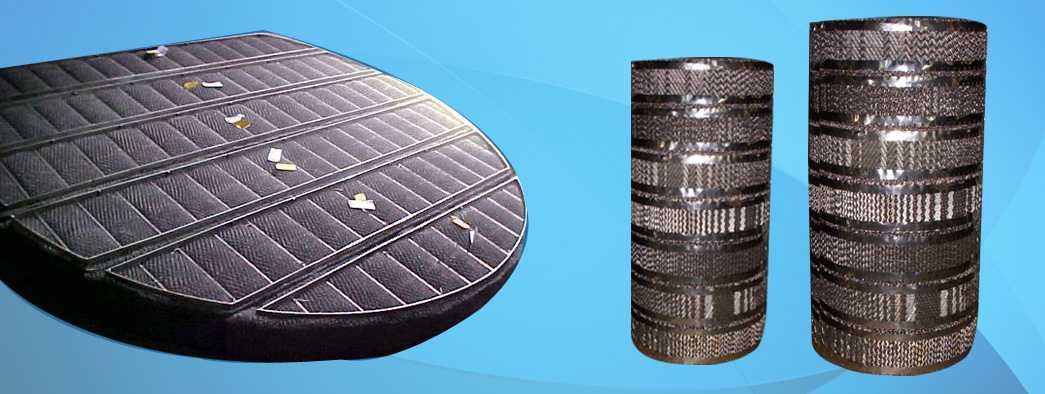

The EVERON HFV (Horizontal Flow - Vertically Palced)

This mist eliminator is designed for horizontal gas flow. In this onfiguration, specially designed sinusoidal vanes having a provision for a phase separation chamber are employed.

The gas flow is split by these vanes and the entrained liquid particles are driven by inertial forces to the walls in the phase separation chambers. Reentrainment is avoided as a separate liquid drainage path is provided in the phase separation

CAPACITY

The EVERON separators working on the inertial separation mechanism can be used efficiently over a wide gas velocity range without a significant loss of droplet removal efficiency. Thus, for situations where wide flow rate ranges are possible, the EVERON is a preferred choice compared to cyclonic type mist eliminators.

The operating velocity is obtained by a force balance between the gravitational, drag and surface tension forces acting on the entrained droplets. A wide operating velocity range is possible & the capacity of the EVERON is only limited by the phenomenon of reentrainment of the coalesced droplets and hence the design velocity has to be kept well below this critical velocity which leads to reentrainment.

EFFICIENCY

EVERONS are largely used for the separation of coarse mist (or spray) from gases and vapours. A limit drop size (Dp) is used to characterize them and it is defined as the smallest particle which can be removed to an extent of 99%. The normal (Dp)are in the region of 25 microns and higher. However, special designs are available for applications requiring removal of particles smaller than this size.

PRESSURE DROP

Due to the large percentage of the cross section available for gas flow, the pressure drop in a vast majority of applications is less than 25-50 mm WG. As mentioned above, for high efficiency applications, a larger pressure drop is to be expected.

APPLICATIONS

Due to its constructional features, the EVERON has a lower tendency to fouling. Recommended areas of operation would therefore include :

- Applications where droplets will be sticky or viscous and will plug conventional Knitted/Fibre Bed Mist Eliminators.

- For systems containing certain solids it would be possible to carry out intermittent cleaning with spray nozzles.

- Situations where wide flow rate ranges are possible which renders the cyclonic type systems unsuitable.

SPECIAL DESIGN FOR HIGH PRESSURE/HIGH EFFICIENCY APPLICATIONS.

EVERGREEN has designed a range of EVERON mist eliminators for critical applications in the oil and gas sector, for high-pressure boiler applications. These are primarily of the EVERON HFV configuration with collection efficiency of essentially 100% for particles 8 microns and larger and pressure drops below 0.1 kg/cm 2 . These are compact designs which are useful in high-pressure installations and offshore platform due to their reduced size. EVERON mist eliminators have now been operating for such critical duties at operating pressures as high as 100 bar. In addition, EVERGREEN also offers designs for horizontal gas flow wherein the EVERMESH media is used as an agglomerator / coalescer for fine aerosols which are subsequently fed into a vane (typically EVERON HFV configuration) for removal as a larger drop.

Alternatively, for vertical gas flows an EVERON VFH mist eliminator is placed as the first stage coarse separator for situations where a high inlet liquid load or a fouling situation is envisaged. An EVERMESH unit is then used to effectively clean/polish these gases downstream of the vane mist eliminator.

PERFORMANCE DATA

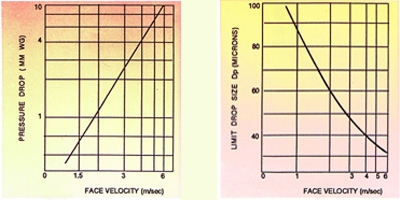

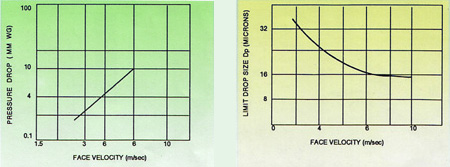

Various mist eliminator configurations are available and typical performance curves are shown below.

EVERON VHF

EVERON HFV - I

Successful areas of application include Evaporators, Exhaust Air Cleaning, Chemical Process Equipment, Air Conditioning & Steam Drying, Air Intake Systems, Natural Gas operations, etc.

EVERON VHF (VERTICAL GAS FLOW)

.gif)

EVERON HFV (HORIZONTAL GAS FLOW)