PRODUCTS » MIST ELIMINATORS

PRODUCTS » MIST ELIMINATORS

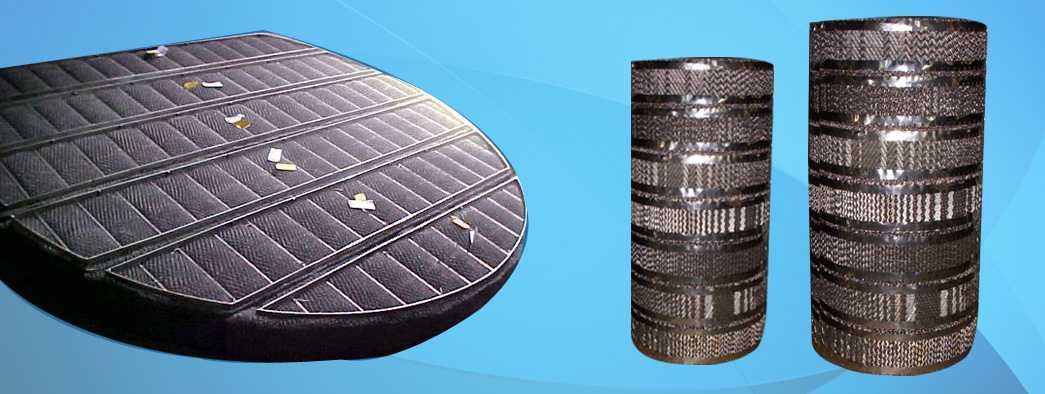

EVERMESH PAD MIST ELIMINATOR

WHAT IS EVERMESH MIST

EVERMESH MIST ELIMINATOR is fabricated in pad form from symmetrical interlocking loops of knitted metal wire or plastic monofilaments. The pad with a high free volume and large impingement area, can be installed in any existing or new process vessel to provide separation efficiencies up to 99% for particles down to five microns at pressure drops in the vicinity of 25 mm WG. The EVERMESH MIST ELIMINATOR is a static, in-line device and in a majority of the cases it can be installed in the evaporator, scrubber, pressure vessel etc., without a special housing. There is practically no maintenance required except for cleaning when used in fouling services.

HOW EVERMESH MIST ELIMINATOR

When vapour carrying entrained liquid droplets or mist passes through the EVERMESH MIST ELIMINATOR, the vapour passes freely through the layered mesh structure of the EVERMESH MIST ELIMINATOR but the liquid droplets, having greater inertia, contact the large wire surface exposed and are briefly held there. As more droplets collect, they coalesce and grow in size and become large enough to drain back into the system. The overhead product is pure vapour containing practically no liquid.

DESIGN AND ENGINEERING DATA

The separating action of a separator largely depends upon the contact surface area necessary for impingement which must be evenly distributed. Generally speaking, a higher free volume leads to a lower pressure drop. In critical cases, it may be necessary to decide whether pressure drop or efficiency should be sacrificed. However, the EVERMESH MIST ELIMINATOR allows the greatest possible efficiency at the lowest possible pressure drop.

EFFICIENCY

Normally EVERMESH MIST ELIMINATOR will remove droplets down to 5 microns with an efficiency upto 99%. This efficiency will vary depending upon the particle size distribution and other operating conditions. Furnished in a wide variety of mesh styles, the EVERMESH MIST ELIMINATOR offers collection efficiency and pressure drop combinations that can be suited exactly to specific process requirements. Special design are now available with higher efficiencies for specific applications.

APPLICATION CONFIGURATION

PRESSURE DROP

Pressure Drop is also a function of separator specifications and is less than 25 mm WG for a majority of applications. In vacuum service, high efficiency is routinely achieved with pressure drop of the order of 5 mm WG.

EVERMESH MIST ELIMINATOR MAKES ANY GOOD PROCESS BETTER

- IMPROVES PROCESS EFFICIENCY.

- ELIMINATES COSTLY LIQUID LOSS.

- SOLVES AIR POLLUTION PROBLEM.

EVERMESH MIST ELIMINATORS

- Distillation Equipment

- Evaporators

- Knockout Drums

- Vacuum Towers

- Scrubbers

- Steam Drums

- Absorbers

- Strippers/Regenerators

DESIGN VELOCITY

The maximum allowable vapour velocity. U, for most systems is calculated according to the equation given below.It is suggested that the design velocity should be 60-75% of U to allow for surges and upset conditions. However, excellent performance is obtained in most systems for velocities 30 - 110% of the maximum allowable vapour velocity. For high pressure & vacuum services the constant K needs a specific design.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SPECIAL APPLICATION :

In addition to the standard and improved styles listed here, specific designs are available for special applications. These include high pressure steam drums, natural gas dehydration plants, multiple effect evaporators, etc.

|

||||||||||||||||||||||||||||||||||||||||||||

SELECTIONS AND SIZE OF AN EVERMESH MIST ELIMINATOR IS DECIDED BY :

- Gas or vapour flow rate and amount of liquid entrained

- Allowable design velocity

- Material of construction

- Droplet size distribution and performance requirement.

- Physical and chemical properties of the gas and liquid phases.

INSTALLATION DETAILS

The wiremesh pad of the EVERMESH MIST ELIMINATOR is sandwitched between a top hold down grid and a bottom support grid. Special grids with a high percentage of open area have been developed for this purpose. The wiremesh pad is resilient and is slightly oversize to provide a snug fit in the vessel. The purchaser should provide a 50 to 75 mm wide annular support ring drilled with 3 to 6 mm diameter holes and welded to the vessel wall. The wiremesh pad and grid assembly is then fastened securely to the grid using 2 mm diameter tie wires (or when specifically required with suitable fasteners). Intermediate support beams are also recommended for all spans larger than 1800-2000 mm.