PRODUCTS » MIST ELIMINATORS

PRODUCTS » MIST ELIMINATORS

EVERFIBRE BED MIST ELIMINATOR

INTRODUCTION

FIBRE BED MIST ELIMINATORS are used to provide the highest possible collection efficiency for process conditions requiring stringent performance levels.

The EVERFIBRE BED MIST ELIMINATOR is result of detailed investigation of mist characteristic, laboratory studies of fibre and surface treatments. Evergreen have over 35 years experience in the design, manufacturing and installation of Candle Filter Elements.

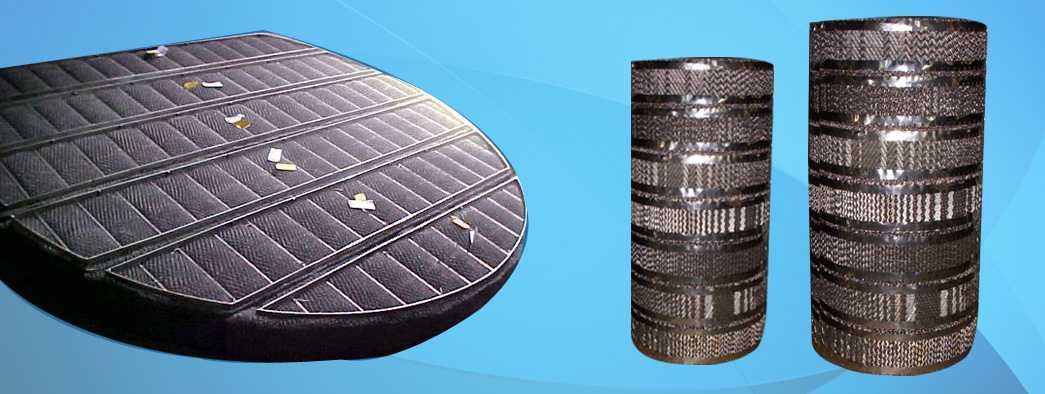

CONSTRUCTION

The unit consists of fibres packed between a pair of concentric screens. Both screens are made of suitable corrosion resistant materials. Type, orientation, fibre bed depth and packing density are tailored to the needs of specific applications.

PRINCIPLE

Coarse mist particles are removed by impaction and direct interception. Finer particles are whisked away through Brownian diffusion. These particles coalesce into a liquid film which is forced by gas flow downstream of the fibre bed. The liquid then flows by gravity into the drain.

APPLICATIONS

The EVERFIBRE Bed Mist Eliminator is designed to rid air/gases of emissions which could harm human and plant life, affect downstream equipment and cause plume opacity. The world is concerned about an endangered environment and for industries conscious about an endangered environment and for industries conscious of the perils of pollution, the EVERFIBRE Bed Mist Eliminator is a viable solution to a vexing problem.

The EVERFIBRE Bed Mist Eliminator finds wide application in the field of sulphuric acid, sulphonation plants, chlorine plants, nitric acid and ammonium nitrate plants and compressed gas applications.

Today, hundreds of these mist eliminators are helping to clear the air in process plants through out the world. Plant managers report that these devices are working satisfactorily and our experienced technical cell has successfully carried out a number of field trials at customer locations.

INSTALLATION CONFIGURATIONS

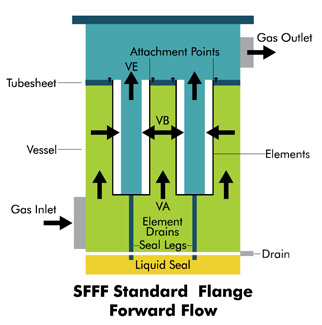

Two possible installation configurations are available.

Standard flange forward flow (SFFF) in which the element hangs from a tubesheet. In this option, the mist laden gases flow from outside the element and clean gas exists through the inner center core.

This installation features ease of installation and maintenance.

The High Efficiency elements are recommended in this configuration.

Reverse-flow upside down (RFUSD) in which the mist eliminator is placed vertically on a tubesheet. In this option, the mist laden gases flow from inside the central core of the element and the clean gas exists through the outside.

This installation will result in reduction of housing vessel size.

Both the HE HFseries mist eliminators are available in this con-figuration.

However due to exit velocity reentrainment consideration The High Throughput elements are recommended only in this configuration.

The Following Table Provides Performance Parameters Of Typical Fibre Materials and Specifications

| HIGH EFFICIENCY | GLASS FIBRE (GFR/GFM) | SMALLEST FIBER DIA. POSSIBLE |

HANGING OR STANDING TYPE |

| COLLECTION MECHANISM | BROWNIAN DIFFUSION | INTERCEPTION | IMPACTION |

| SELECTION CRITERIA | HIGHEST EFFICIENCY | INVISIBLE STACK I EMISSION < 20MG/NM3 |

CORROSION PROTECTION |

| DESIGN CRITERIA | MIST REMOVAL 100% REMOVAL > 3 MICRON 99% REMOVAL < 3 MICRON |

150-250 MM H20 PRESSURE LOSS |

LESS THAN 0.25 M/SEC BED VELOCITY |

| HIGH FLOW | GLASS FIBRE (GFC) | COARSE FIBER DIAMETER | STANDING TYPE |

| COLLECTION MECHANISM | COALESCENCE | INTERCEPTION | IMPACTION |

| SELECTION CRITERIA | HIGH GAS VOLUME THROUGHPUT |

LIMITED SPACE | DRAINAGE METAL MESH OPTIONAL |

| DESIGN CRITERIA | 100% REMOVAL > 3 MICRON 70%-95% REMOVAL < 0.5-3 MICRON |

100-200 MM H20 PRESSURE LOSS |

0.8 - 2.0 M/SEC BED VELOCITY |

| POLYPROPYLENE MEDIA | POLYPROPYLENE FIBER (FPM) | SMALLEST FIBRE DIAMETER | HANGINNG OR STANDING TYPE |

| COLLECTION MECHANISM | BROUNIAN DIFFUSION | INTERCEPTION | IMPACTION |

| SELECTION CRITERIA | HIGHEST EFFICINCY MIST REMOVAL | ALKALINE PROCESS CONDITION |

AIR / HYDROGEN SERVICE |

| DESIGN CRITERIA | 100% REMOVAL > 3 MICRON 95% REMOVAL < 1-3 MICRON 90% REMOVAL 0.5-1 MICRON |

120-250 MM H20 PRESSURE LOSS |

< 0.2 M/SEC BED VELOCITY |

SALIENT FEATURES

- Mist loading fluctuation (within design values) do not interfere with particle removal efficiencies. Stable operation is ensured at high turndown ratios.

- Designs are computerized for an optimum sized unit selection based on separation efficiency and allowable pressure drop with an aim to maintain minimum installed and operating costs.

- Efficiency of unit is guaranteed to conform to mist emission standards set by pollution boards in India (MINAS) as well as those stipulated by Environmental Protection Agency (EPA), U.S.A.