PRODUCTS » STRUCTURED COLUMN PACKINGS

PRODUCTS » STRUCTURED COLUMN PACKINGS

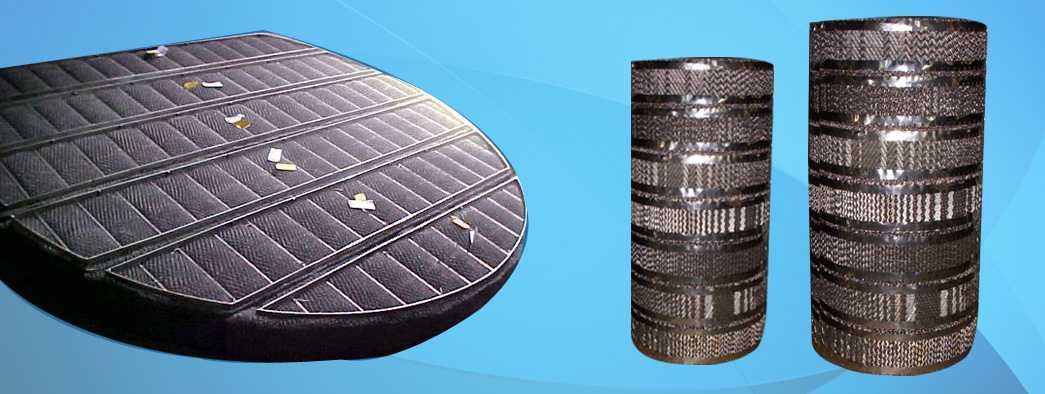

HIGH EFFICIENCY & LOW PRESSURE DROP COLUMN PACKING

HYFLUX is a family of structured tower packings, which are particularly useful when a moderate to large number of theoretical stages have to be accommodated in a limited height of the tower.

HOW IT WORKS

The open structure formed due to the proprietary lay of the filaments, the unique stitches employed and the special crimping and plying form tortuous channels for liquids which can continuously combine, divide and recombine for optimum mixing and contact with vapour. This results in intimate mixing between vapour passing upward through the controlled interconnecting passageways and the thin film of liquid flowing down the capillary wire network of the packing. The unique interaction results in high mass transfer rates (maximum separation efficiency) while maintaining low resistance to flow (low P/ theoretical stage).

TECHNICAL DATASPECIFICATIONS |

|

| HETP | |

| NTU/metre | |

| P/ theoretical | : 0.05 - 0.75 mm Hg. plate |

| Vapour load | : 0.2 - 2.75 F factor m/s |

| Liquid load | : |

| Liquid holdup | : 3 to 8% w/w |

LIQUID DISTRIBUTION

For better operation of Hyflux packing it is necessary to have a good initial multipoint distributor. Because of the capillary action of multifilaments, the wall effects are nearly eliminated. However, for column heights larger than 3 metres an intermediate redistributor would be recommended. EVERGREEN offers a full line of column internals to complement HYFLUX high efficiency packing.

MATERIALS OF CONSTRUCTION

Any material which can be drawn into a fine wire or filament can be used in the manufacture of HYFLUX packing. However, stainless steel 304 and 316 grades are readily stocked and other higher alloys are available on order.

INSTALLATION

HYFLUX is supplied as a 150 mm height module of the same diameter as the nominal bore of the column. The column must be free from all internal projections and in the case of welded columns the internal welds should be ground smooth. Only the simplest type of support is required - usually two bars at right angles or in larger towers parallel bars and cross bars at 150 mm pitch.

Successive modules of HYFLUX are inserted into the top of each section of tower and pushed gently down towards the support grid. A disc of wood mounted on a pole permits the packing to be pushed without risk of damage. Care should be taken to ensure than successive modules of HYFLUX have their crimps going in opposite direction (i.e. staggered).

ADVANTAGES

» |

Improve performance of existing columns. You can upgrade existing processes by replacing random packing or trays with HYFLUX column packing. This simple change can result in increased product quality, higher production capacity and lower pressure drop. Substantial energy savings are possible by permitting the use of lower reflux ratios resulting in lower re-boiler duty. |

» |

Reduced cost of new packed column systems. The high efficiency of HYFLUX permits significant reductions in tower diameter and height, minimizing structural, foundation, piping, insulation, and installation costs on new projects. |

» |

Turn down - Due to its capillary nature, the efficiency of HYFLUX column packing increases with decreasing loading thereby providing an extremely wide range of operating capabilities. |

APPLICATIONS

» |

Vacuum distillation service where pressure drop across the column is critical. |

» |

Separation of close boiling components / isomers which requires a very large number of theoretical plates. |

» |

A combination of (1) & (2) and where the components are thermally unstable. In such a case, HYFLUX packing are indispensable. |

Our technical department will assist you in solving your specific distillation design problem. Please provide relevant data to enable us to furnish our recommendations/quotation.