PRODUCTS » COALESCERS

EVERSEP LIQUID - LIQUID COALESCER

INTRODUCTION

The chemical processing and refining industry encompasses a number of applications where two liquid phases are made to intimately contact one another. This leads to a dispersion of one liquid phase in the other and the key to effective process performance is an efficient way to separate the two phases once again.

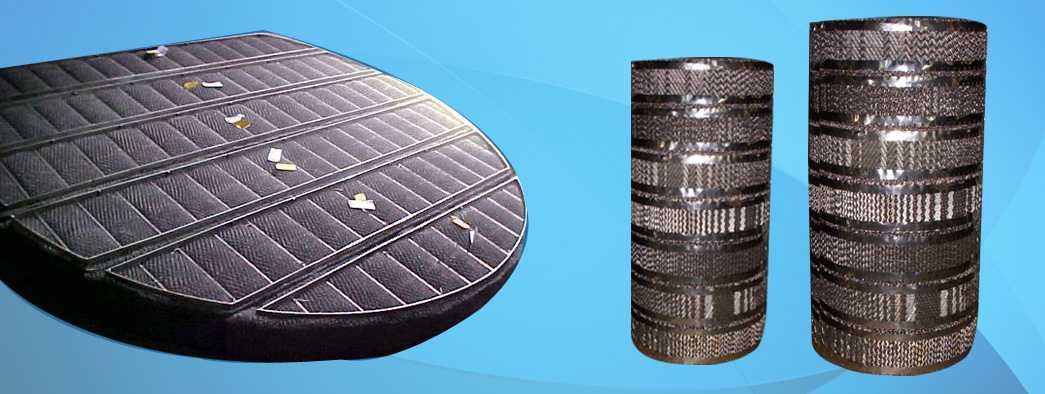

The EVERSEP range of liquid - liquid Coalescers are a family of specially designed equipment to optimize the coalescence of droplets and thereafter to separate these coalescer droplets into their respective phases.

PERFORMANCE

Evergreen has at its disposal a large number of configurations of coalescers for the myriad requirements of its customers. These include standard mesh pads, coknits of materials of differing surface energies, elements of specialty micro fibres, parallel plate assemblies, etc. A modern coalescer assembly allows a capacity increase of 50% - 200% of conventional gravity settlers. The removal rates or efficiency levels achievable are an outlet stream quality with a dispersed phase concentration of 20-200 ppm in the continuous phase and vice-versa. These values refer to the free amount of liquid (over & above the solubility limits).

The design of a coalescer is a blend of science and art. Trace impurities, pH changes, presence of surfactants and solids and various other factors can dramatically alter coalescer performance. In view of the above, we strongly recommend a laboratory test followed by pilot plant trials or onsite slip stream testing before installing a full size commercial unit.

INSTALLATION

Our team of engineers will assist you at various stages of implementation and as a first step we will request detailed information from your end in terms of complete coalescer data questionnaire form.